Surprise!!! Axle Build. 8.8/D30 4.10

#47

Seasoned Member

Thread Starter

Join Date: Aug 2010

Location: Grand Junction, CO

Posts: 330

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1999

Model: Cherokee

Engine: 4.0L I-6

#48

Seasoned Member

Thread Starter

Join Date: Aug 2010

Location: Grand Junction, CO

Posts: 330

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1999

Model: Cherokee

Engine: 4.0L I-6

More progress...and Surprises.

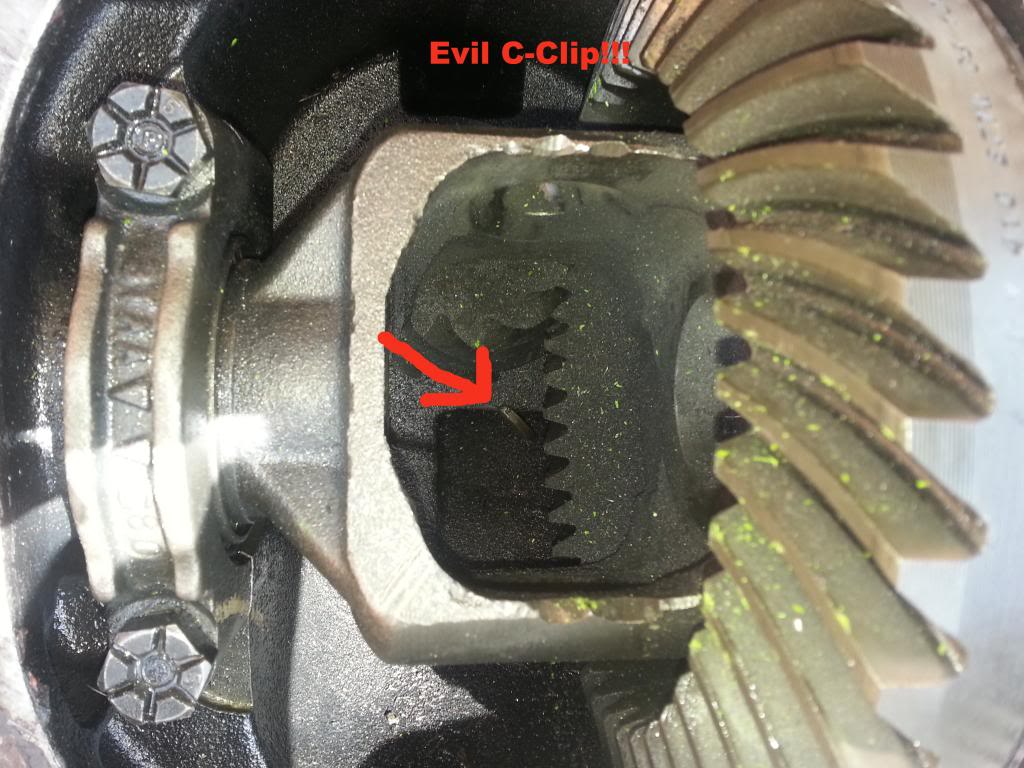

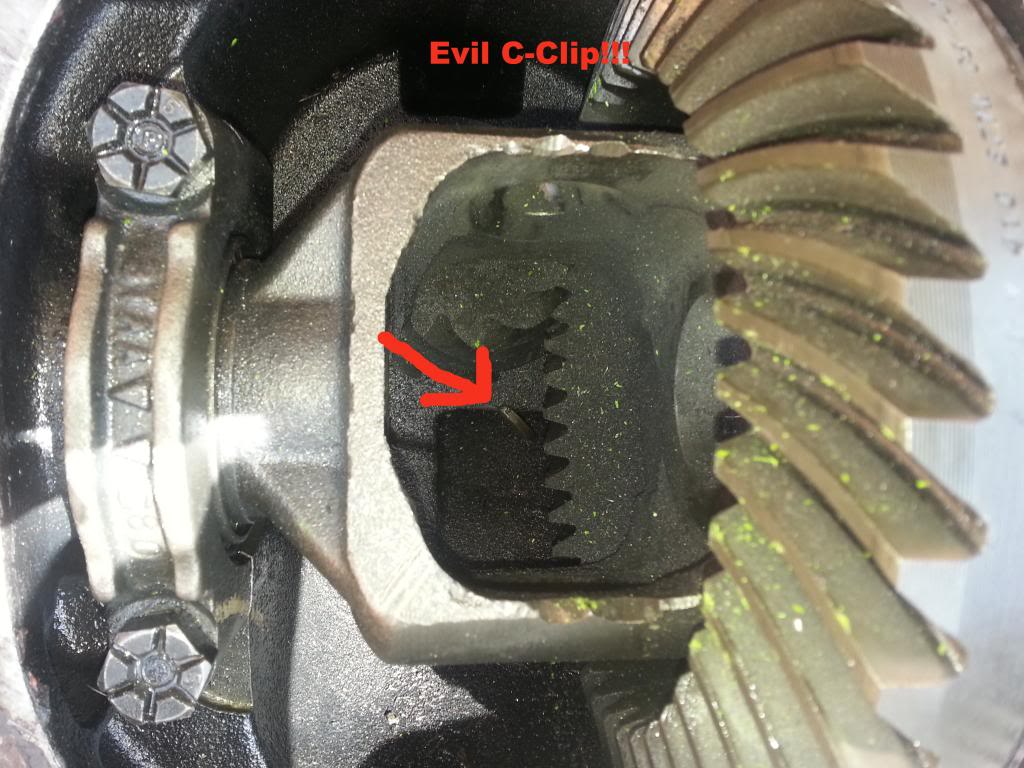

Got the other stupid C-Clip out!

For sale...slightly ground down Ford 8.8 MiniSpool. $15!!! Not too bad.

Other pics

And of course...it wouldn't be me without a Surprise or two...

I cleaned out the innards, lots of C-Clip shavings all over. I think I got everything out...

But of course, the pinion does not turn easy. Not sure if something fell down in and it is causing binding behind the pinion...or if I'm just destined to learn everything there is to learn about Axles and fully rebuild this beast!!!

Got the other stupid C-Clip out!

For sale...slightly ground down Ford 8.8 MiniSpool. $15!!! Not too bad.

Other pics

And of course...it wouldn't be me without a Surprise or two...

I cleaned out the innards, lots of C-Clip shavings all over. I think I got everything out...

But of course, the pinion does not turn easy. Not sure if something fell down in and it is causing binding behind the pinion...or if I'm just destined to learn everything there is to learn about Axles and fully rebuild this beast!!!

Last edited by eggdashure; 04-06-2013 at 04:41 PM.

#49

Seasoned Member

Thread Starter

Join Date: Aug 2010

Location: Grand Junction, CO

Posts: 330

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1999

Model: Cherokee

Engine: 4.0L I-6

Good weekend to work on the axle!

So, not wanting to cut and grind in the dark tonight, I decided to throw the 8.8 carrier up on the bench and give it a thorough cleaning. Plus, I wanted to see how the spiders fit...

For once, no surprises! They fit and work great...though I panicked briefly when I tried to drop one of the side spiders onto an axle shaft and it didn't seem to fit. I figured, knowing my luck, I had 29 spline spiders, but promptly pulling it up and twisting it fell right on.

Oh, and since the D30 carrier was sitting right there...I decided to look at it even more closely. I think all I really need to salvage this thing (carrier anyways) is a new set of spiders. Things aren't as bad as my initial assessment. But still, I think the PO of this D30 axle must have paid a buddy in beer to install the gears...and they drank it before starting.

For one, there were no shims at all, a race was missing and somehow he installed the 4.10 gears without grinding any teeth. Simply put, I can't remove the center pin unless I pull the ring. Maybe this is by design...I dunno.

Anyways, one last pic and I'm done for the night. Anyone curious what bearings look like when you do not use a race?

So, not wanting to cut and grind in the dark tonight, I decided to throw the 8.8 carrier up on the bench and give it a thorough cleaning. Plus, I wanted to see how the spiders fit...

For once, no surprises! They fit and work great...though I panicked briefly when I tried to drop one of the side spiders onto an axle shaft and it didn't seem to fit. I figured, knowing my luck, I had 29 spline spiders, but promptly pulling it up and twisting it fell right on.

Oh, and since the D30 carrier was sitting right there...I decided to look at it even more closely. I think all I really need to salvage this thing (carrier anyways) is a new set of spiders. Things aren't as bad as my initial assessment. But still, I think the PO of this D30 axle must have paid a buddy in beer to install the gears...and they drank it before starting.

For one, there were no shims at all, a race was missing and somehow he installed the 4.10 gears without grinding any teeth. Simply put, I can't remove the center pin unless I pull the ring. Maybe this is by design...I dunno.

Anyways, one last pic and I'm done for the night. Anyone curious what bearings look like when you do not use a race?

Last edited by eggdashure; 04-13-2013 at 12:45 PM.

#54

Seasoned Member

Thread Starter

Join Date: Aug 2010

Location: Grand Junction, CO

Posts: 330

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1999

Model: Cherokee

Engine: 4.0L I-6

True, my gripes were more that the guy lied about what I was supposedly getting. A D44 with a Detroit locker is very different from an 8.8 with a mini spool. But, I should have known that wasn't true for $200.

Now that I have the C Clips out I''m feeling much better about my purchase.

Now that I have the C Clips out I''m feeling much better about my purchase.

#55

Seasoned Member

Thread Starter

Join Date: Aug 2010

Location: Grand Junction, CO

Posts: 330

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1999

Model: Cherokee

Engine: 4.0L I-6

So begins the big push to get this beast of an 8.8 in! My goal is to have it in by the end of the week...doubtful that will happen, but I'm actually fairly close.

I knocked off most of the remaining metal before I ran out of cutting wheels.

And straightened and painted the dust shields...now if I can remember which way they go on...

Oh, and I was able to air-blast out a bunch of junk that was causing binding in the pinion. Rolls smooth as glass now!

I knocked off most of the remaining metal before I ran out of cutting wheels.

And straightened and painted the dust shields...now if I can remember which way they go on...

Oh, and I was able to air-blast out a bunch of junk that was causing binding in the pinion. Rolls smooth as glass now!

#56

Seasoned Member

Thread Starter

Join Date: Aug 2010

Location: Grand Junction, CO

Posts: 330

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1999

Model: Cherokee

Engine: 4.0L I-6

Finally done with cutting all the metal off and grinding. Tomorrow I will pull my old axle and line up the 8.8 and depending on how much time I have, I may weld on the perches. Probably just tack weld everything and do it properly the following day. We'll see how it goes.

#57

Since the 8.8 is narrower and has an offset diff, lining it up with your existing axle will be a tad more difficult. I'd recommend marking the perch location on the tubes and placing the complete axle under the rig with the perches un-tacked. This will allow you to raise/lower the pinion with a floor jack to set the pinion angle perfectly.

Once you've got the right angle....tack the perches in place. Then do the same for the shock mounts. A string or straight edge from the stud to the center of the upper mounting holes will make life a little easier.

Once you've got the right angle....tack the perches in place. Then do the same for the shock mounts. A string or straight edge from the stud to the center of the upper mounting holes will make life a little easier.

#58

Seasoned Member

Thread Starter

Join Date: Aug 2010

Location: Grand Junction, CO

Posts: 330

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1999

Model: Cherokee

Engine: 4.0L I-6

Thanks Serious, I'll take all the advice I can get! I'm a bit concerned about my Bilstein shocks. The guy I bought them from forever ago, said they came off of a Wrangler with a 3" lift. They worked great on my when the mounts extend below the axle. When they are inline...I wondering how much that will limit my upward travel. Especially when I load it down with a pop-up camper. Won't know until I try!

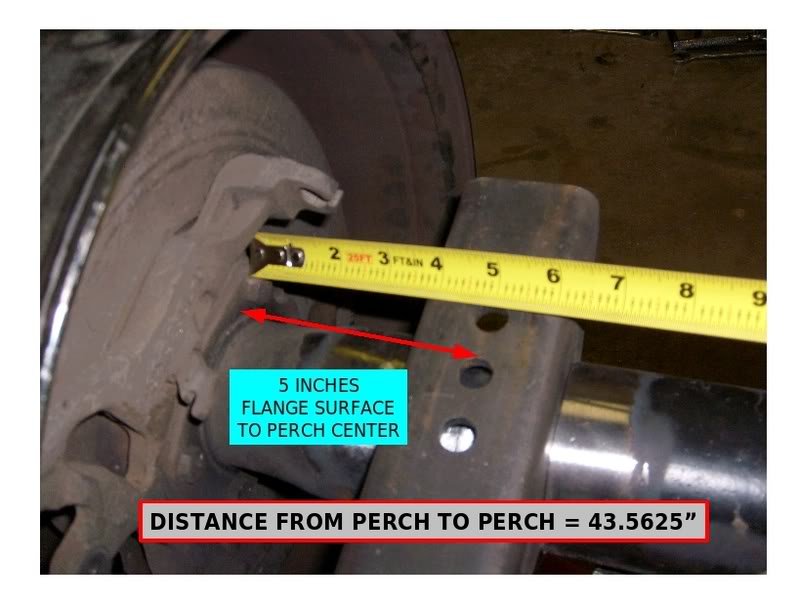

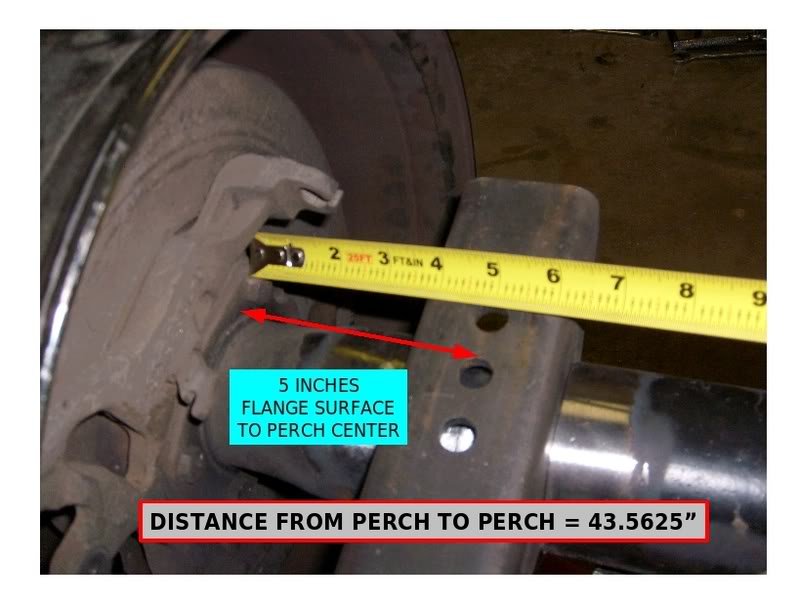

As far as the perches, I'm planning to reference an article I found over at NAXJA. He says to space the perches 5 inches on center from the outside flange. Should work:

More parts today...I went down to Napa to get the rotors turned. The tech looked at me and said "Uh...tomorrow-ish." So I decided to try O'Reilly's and they said they could do them while I waited...until they measured the thickness. After machining they would have been at minimum allowed. Thankfully, it was only $10 more per side to get new over machining. Also grabbed the new brake pads. How can they offer a lifetime warranty on brake pads?! Seemed odd to me.

Oh, and a new steel brake line. When we measured the old bent line, it came out to about 53", I opted for the 60" line so I have some wiggle room.

As far as the perches, I'm planning to reference an article I found over at NAXJA. He says to space the perches 5 inches on center from the outside flange. Should work:

More parts today...I went down to Napa to get the rotors turned. The tech looked at me and said "Uh...tomorrow-ish." So I decided to try O'Reilly's and they said they could do them while I waited...until they measured the thickness. After machining they would have been at minimum allowed. Thankfully, it was only $10 more per side to get new over machining. Also grabbed the new brake pads. How can they offer a lifetime warranty on brake pads?! Seemed odd to me.

Oh, and a new steel brake line. When we measured the old bent line, it came out to about 53", I opted for the 60" line so I have some wiggle room.

#59

Seasoned Member

Thread Starter

Join Date: Aug 2010

Location: Grand Junction, CO

Posts: 330

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1999

Model: Cherokee

Engine: 4.0L I-6

More progress, and only one surprise!

Everything is back in place!

The surprise came when I dropped the carrier in. It spun fine...for a half spin, then it started to bind. What the...oh wait, the axle is sitting opposite of how you took it out, you need to swap the spacers and clamps dummy!

So...it took some effort, but I got the carrier back out, swapped the equipment and dropped it back in. This time it rolled nice and smooth.

What's left to finish before installation:

1) Bend the new brake line in place and figure out how to attach.

2) Install the calipers, pads and rotors (E-Brake will come later, my current Y connector won't budge. Started to bend things. Left it soaking in penetrating oil.)

3) Fill it with diff fluid

4) RTV Seal on the Solid cover, reattach

5) Install Pinion Adapter

Installation:

1) Remove the front drive shaft!!!

2) Remove the 8.25 (Check angle)

___a) Pull tires

___b) Disconnect rear drive shaft

___c) Remove U-bolts/Plates

___d) Disconnect brake lines

___e) Remove shocks

___f) Slide 'er out

3) Slide the 8.8 in place

4) Adjust pinion angle (16 or 17 degrees? We'll see...)

5) Tack weld the perches (Shock and Spring)

6) Slide it back out

7) Final weld everything in place

8) Finish painting

9) Slide it back in

10) Attach the brakes

11) Connect the drive shaft

12) Fasten new U-bolts/plates

13) Re-install shocks

14) Bleed the brakes

15) Tires

16) Happiness?

Then

Now (Yes I know the brake brackets are backwards!)

Everything is back in place!

The surprise came when I dropped the carrier in. It spun fine...for a half spin, then it started to bind. What the...oh wait, the axle is sitting opposite of how you took it out, you need to swap the spacers and clamps dummy!

So...it took some effort, but I got the carrier back out, swapped the equipment and dropped it back in. This time it rolled nice and smooth.

What's left to finish before installation:

1) Bend the new brake line in place and figure out how to attach.

2) Install the calipers, pads and rotors (E-Brake will come later, my current Y connector won't budge. Started to bend things. Left it soaking in penetrating oil.)

3) Fill it with diff fluid

4) RTV Seal on the Solid cover, reattach

5) Install Pinion Adapter

Installation:

1) Remove the front drive shaft!!!

2) Remove the 8.25 (Check angle)

___a) Pull tires

___b) Disconnect rear drive shaft

___c) Remove U-bolts/Plates

___d) Disconnect brake lines

___e) Remove shocks

___f) Slide 'er out

3) Slide the 8.8 in place

4) Adjust pinion angle (16 or 17 degrees? We'll see...)

5) Tack weld the perches (Shock and Spring)

6) Slide it back out

7) Final weld everything in place

8) Finish painting

9) Slide it back in

10) Attach the brakes

11) Connect the drive shaft

12) Fasten new U-bolts/plates

13) Re-install shocks

14) Bleed the brakes

15) Tires

16) Happiness?

Then

Now (Yes I know the brake brackets are backwards!)

#60

Seasoned Member

Thread Starter

Join Date: Aug 2010

Location: Grand Junction, CO

Posts: 330

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1999

Model: Cherokee

Engine: 4.0L I-6

Ready to go in!!!

This things weighs a ton with everything on it.

Wife needs her Jeep tomorrow, hopefully will have the rest of the week to finish installing...

Now that everything is cleaned up...I kinda hate the half-assed job the PO did on the brace. I certainly don't want to mess with removing it, but still...when the axle is clean it's much more noticeable.

This things weighs a ton with everything on it.

Wife needs her Jeep tomorrow, hopefully will have the rest of the week to finish installing...

Now that everything is cleaned up...I kinda hate the half-assed job the PO did on the brace. I certainly don't want to mess with removing it, but still...when the axle is clean it's much more noticeable.